Mineral Insulated Cable: A History

Heatizon’s Hott-Wire MI cable traces its origins back to 1896 when the first patent for Mineral Insulated Cable was issued. The cable was used on ships and other projects in the years leading up to World War Two when it was used in military equipment. MI cable is very durable and used frequently in powering and controlling critical equipment including nuclear reactors, fire alarms, and emergency systems. The 1930s saw the use of MI cable in Heat Tracing with cable designed specifically for this use entering production in the 1950s.

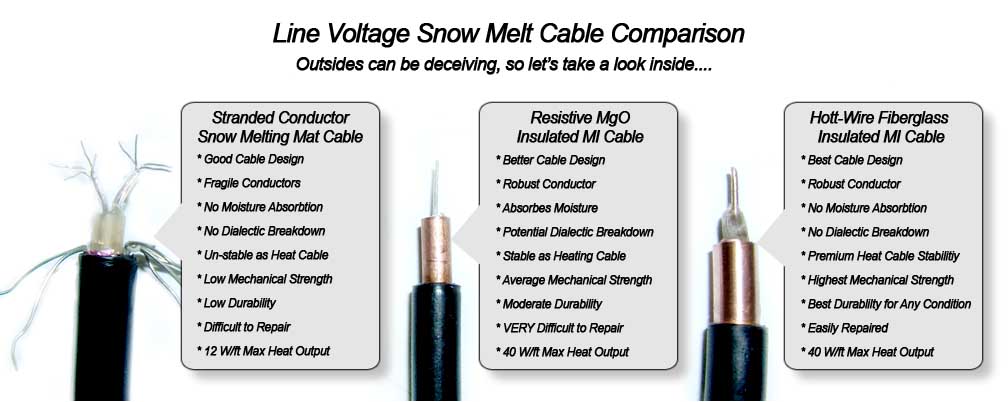

With all of this history, it may seem like all mineral insulated cables are the same, however construction, durability, and lifespan all varies across manufacturers. Let’s take a look at what makes Hott-Wire MI cable stand out for snow melting.

The cold leads (non heating cables which power the system) come pre connected from the factory, meaning no need to splice cables during installation. This connection is also stronger than those made in the field.

Additionally, the cold leads are suitable for direct burial, meaning they can be embedded in the concrete or asphalt without conduit.

Hott-Wire is tested to more rigorous UL standards than other snow melting cables.

The insulator used in Hott-Wire mineral insulated cable does not absorb moisture, which better protects the cable.

Hott-Wire is easier to repair than similar MI cables.

Snow melting systems using Heatizon’s Hott-Wire make use of “jumpers” to protect the cable in crack control joints.

Hott-Wire MI cable is an improvement on 100 years of history, making it a premier snow melting solution. Backed with a 10 year warranty, and tailored to each project by our distributors, Heatizon Hott-Wire is hard to beat. Hott-Wire installs in new pour asphalt and concrete, under pavers in a sand bed, or retrofit into existing surfaces via saw cuts. To learn more about Hott-Wire and our other snow melting products, visit: http://www.heatizon.com/products/radiant-snow-melting